Engineering personnel with extensive boiler design & diagnostic expertise.

BOILER DESIGN & DIAGNOSTICS

Defective steam generation equipment may impose significant financial losses on plant owners which can justify recovery action. Often the defects causing these losses could have been avoided if the boiler design had conformed with best practice guidelines. Conversely, there are circumstances where poor steam plant availability or defective boiler performance that is caused by maintenance and/or difficult operational issues is incorrectly attributed to boiler design.

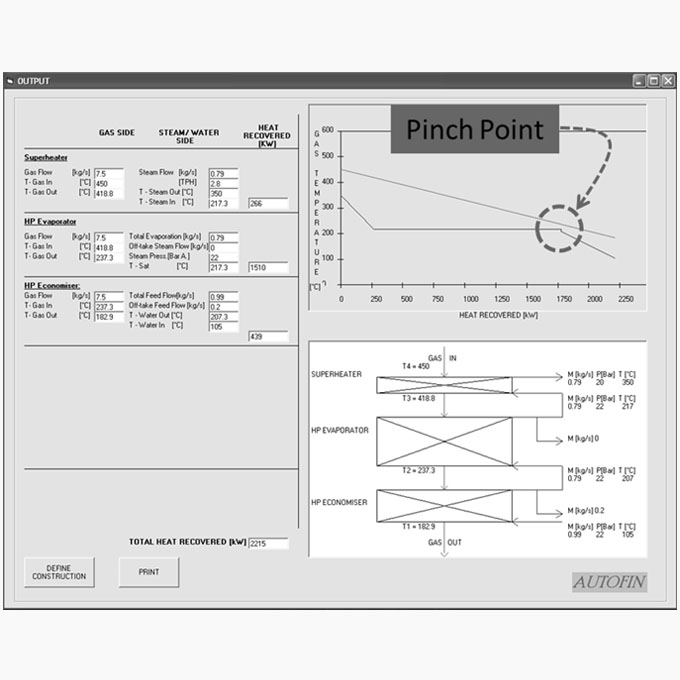

Boiler heat transfer is significantly different to that of a typical industrial process and needs to be analyzed and modelled using purpose-built software. Our extensive range of boiler performance modelling software includes software packages that model the entire gas side process within almost any boiler. The evaporative surfaces of a boiler should achieve an indefinite operating life provided the circulation system is correctly designed and the water treatment management is satisfactory.

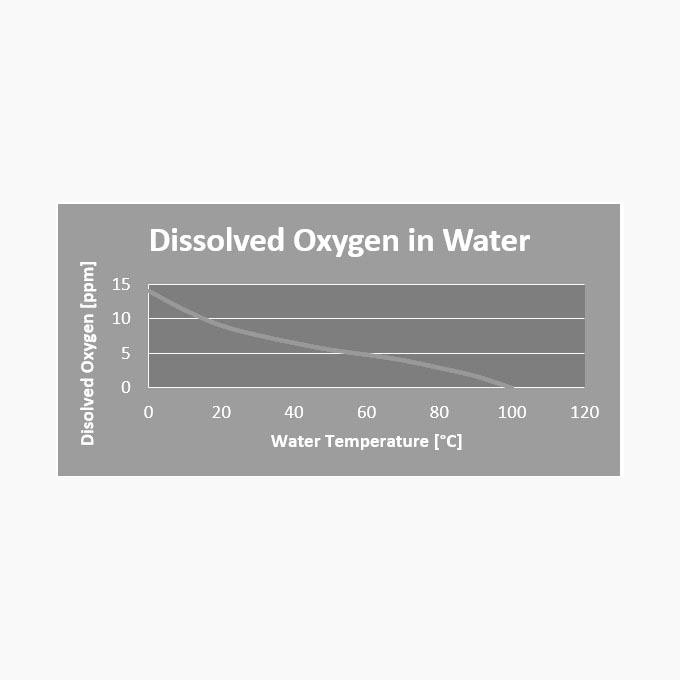

However tube failures in furnaces and evaporative surfaces are surprisingly common and can force boiler plant to be shut down unexpectedly. Metal fires within boilers can be extremely dangerous and may cause extensive catastrophic damage to the boiler and its auxiliary equipment. This is because the fire which often develops at the cooler, back end of the boiler can reach an intensity that causes the plain boiler tubes or tube fins to combust and burn. Once almost exclusively associated with oil fired boilers, the increased combustion of biomass fuel streams has seen an increasing number of metal fires beginning to occur in solid fuel boiler applications. In the early days of steam power, boiler explosions were common place. In fact before 1780 boilers rarely operated above 1 or 2 [psi]. This was a limit intended to reduce the frequent number of boiler explosions that were occurring at that time. More advanced higher steam pressure designs did not enter commercial production until after 1800, by which time the concept of “strong steam “ was coined to describe a boiler operating at or above 30 [psi]. A well-designed boiler circulation system is usually very robust and able to withstand a wide range of operational upset conditions. Conversely a poorly designed system may exhibit a multitude of operational problems such as: frequent tube failures, drum level control instability, superheater tube failures and turbine fouling. Design Boiler has been addressing poor combustion and emission problems on biomass / wood waste boilers for many years. Often high emissions are a direct result of poor combustion and this that overloads the dust collector by producing an excessively high inlet dust burden. The two most common causes of internal boiler corrosion are:

a) Oxygen attack; or

b) Acid attack following chemical cleaning.

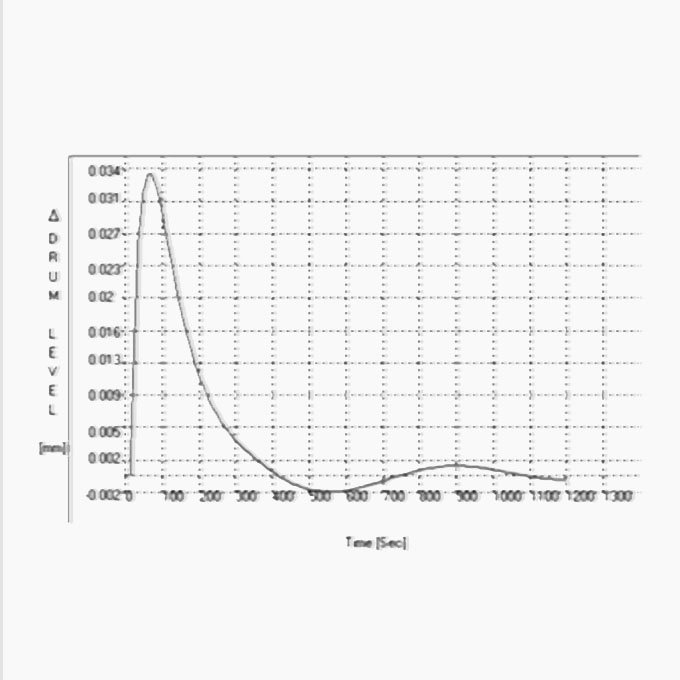

Their can be other types of corrosive attacks on the tubes such as caustic gouging which is related to hydrogen embrittlement, but these are often associated with other factors such as circulation deficiencies. Design Boiler have developed software that is able to simulate the dynamic response of a boiler control system to rapid changes in boiler load.

Sudden changes in steam demand can cause rapid rises in steam pressure that may lift safety valves. The lifting of safety valves may then lead to a sudden drop in boiler pressure causing drum level instability and this can trip the boiler on high steam drum water level.

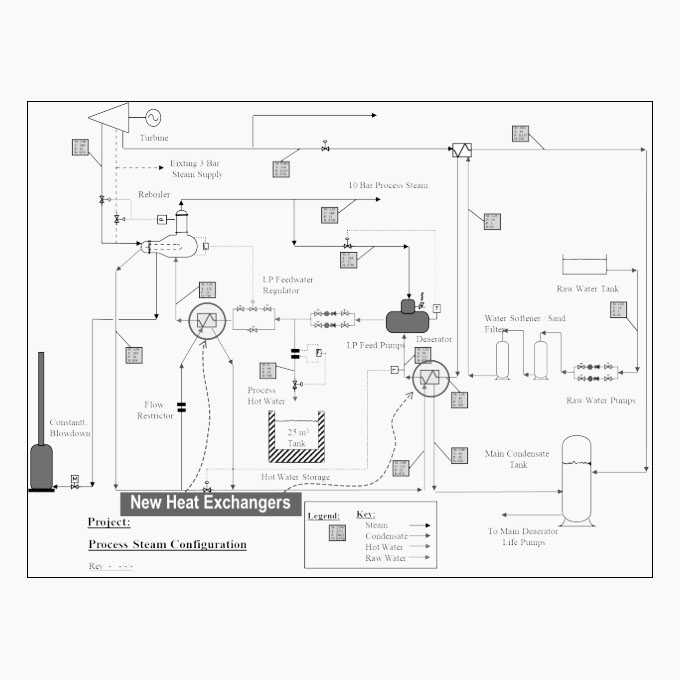

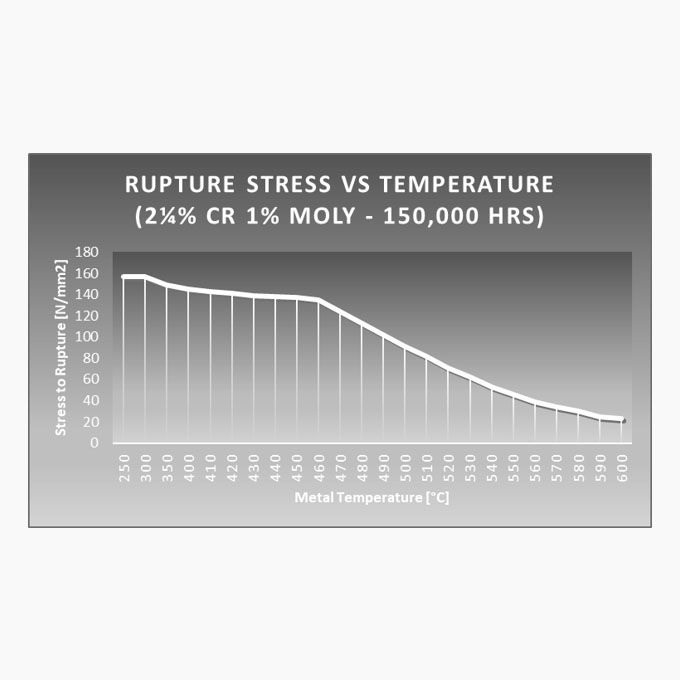

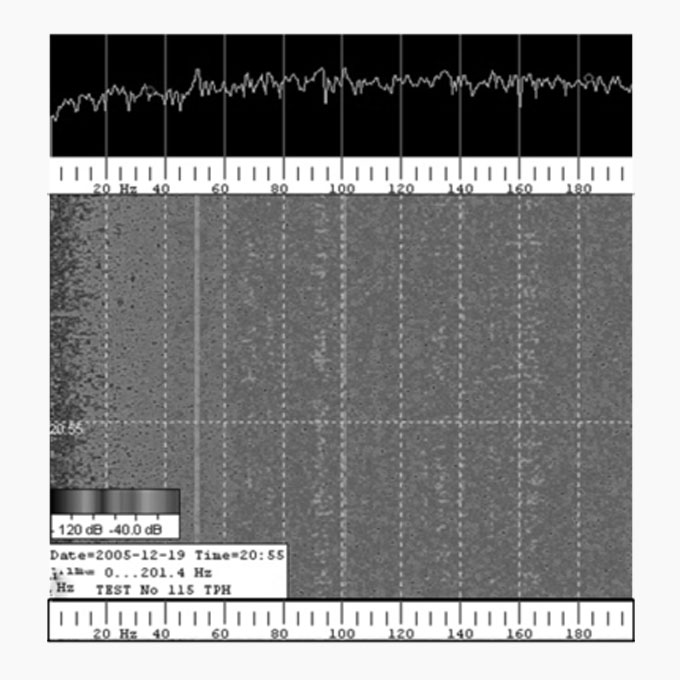

The ability to recover from this type of upset condition depends on a boiler’s control settings, it’s thermal inertia, steam drum size and combustion system capacity. Many boiler plant problems can be difficult to diagnose and fix. Boilers operate under extreme conditions and can sometimes require experienced and specialized expertise to resolve challenging operational problems that may be encountered. Design Boiler is able to mobilize these specialized boiler plant testing and diagnostic services to most global locations. Our personnel are certified for confined space entry and have been trained to internationally recognised BOSIET & HUET systems for immediate off shore mobilization. Vibration can impose major restrictions on a boiler’s steam generating capacity and inflict significant long term structural damage. Typically vibrations will occur above a distinct threshold load or within a very narrow operating load range. If the boiler is operated above or within this load profile for extended periods, it can sustain substantial damage. The utilization of waste heat in industry for the production of steam to generate electricity has grown steadily since the 1970’s. Rising fuel and electricity costs along with increasing concerns about environmental emissions have seen a gradual rise in the number of cogeneration and combined heat & power [CHP] plants globally. Design Boiler has been involved in the design and the diagnostics of problems with HRSG’s for many years. Our technology has also been utilized to verify the suitability of deck mounted HRSGs in key offshore marine installations and to design HRSG’s for industrial co-generation plants. Design Boiler is skilled and experienced in undertaking the necessary computer modelling , design work and field testing required for converting oil fired boilers to gas firing. Typically an oil fired Marine boiler destined for operation on an off shore Floating Production Storage & Offloading [FPSO] platform will need conversion from oil to gas firing. Design Boiler will receive a request to carry out the necessary redesign of the boiler and prepare the required documentation for submission to the relevant marine class authority ( ABS, Lloyds, DNV etc.) Pulverized coal [PC] firing can pose unique challenges such as poor grinding performance, high carbon in ash, slagging problems and excessively high furnace heat fluxes due to combustion related issues. There are many different pulverizing systems and each has its own specific requirements. A poorly designed or problematic steam cycle can impact on overall plant efficiency and significantly increase energy costs. High flash steam losses and excessive condensate makeup are all symptoms of a badly balanced steam cycle which can have detrimental effects on the performance of downstream appliances such as deaerators and steam turbines. Design Boiler has the necessary computer modelling resources and expertise to determine metal temperatures for the selection of tube materials to achieve an acceptable design life. Superheaters operate within a very arduous environment and are often designed at the extreme end of their tube’s metallurgical limits. As well as being the first receiver of the hottest flue gases generated within the furnace, they are constantly subject to direct radiation from the combustion process. Most boiler design standards (ASME, BS, ISO, Lloyds, ABS etc) require the superheater to be designed to achieve a minimum design life in terms of operating hours. For example, BS & ISO standards require the superheater to be designed for a minimum of 100,000 hours. This requires the likely metal temperatures that the superheater will be subject to during normal operation to be determined and that an appropriate tube material is selected to withstand those temperatures. It was the Arab Oil Embargo of the 1970’s that forced industry to become more energy efficient and invest in low grade heat recovery systems. Following this global event it was soon realized that the cost saving engineering strategies utilized in the design of waste heat recovery systems also produced significant benefits for the environment.Boiler Forensic Analysis & Expert Witness Services

Boiler Performance Analysis & Computer Modelling

Boiler & Superheater Tube Root Cause Failure Analysis

Boiler Catastrophic Fire Investigations

Boiler Explosion Investigations

Boiler Circulation Analysis

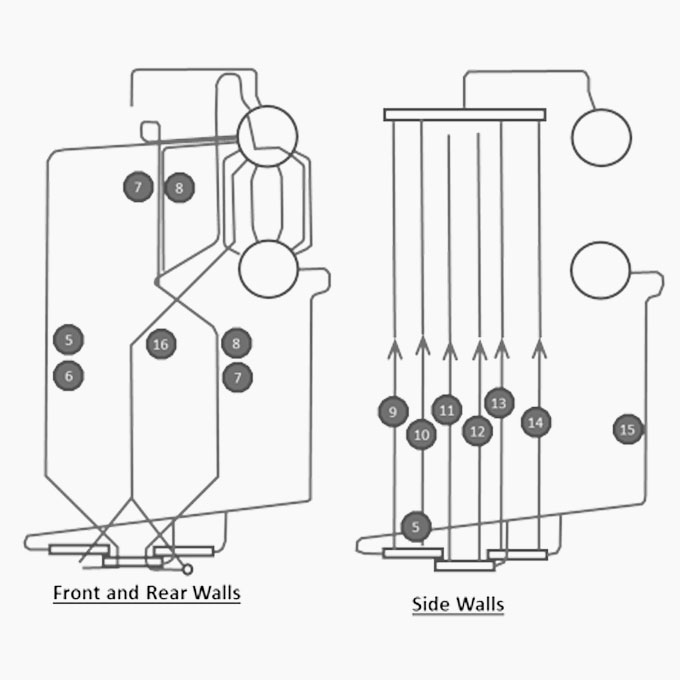

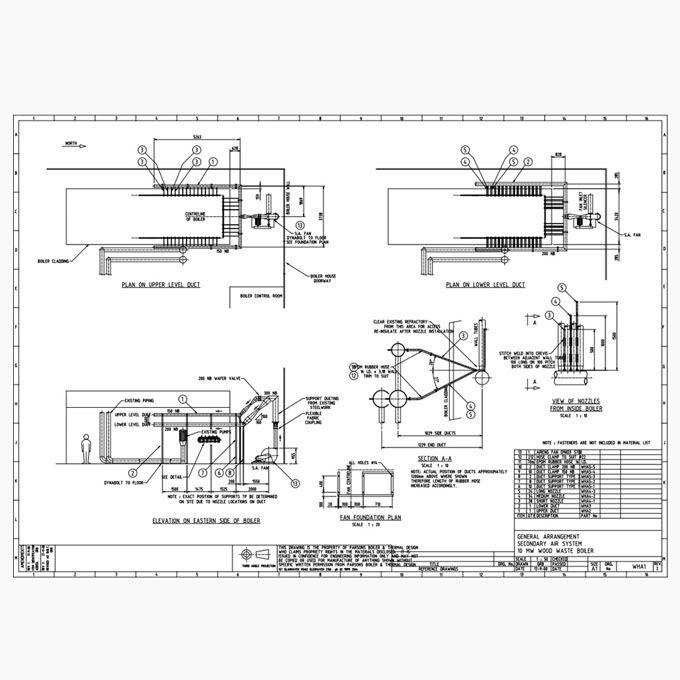

Boiler Combustion & Emission Optimisation

Boiler Corrosion Investigation

Boiler Dynamic Analysis

Boiler Plant Testing & Diagnostics

Boiler Tube Bank and Furnace Vibration

Cogeneration / Combined Heat & Power [CHP]

Heat Recovery Steam Generator [HRSG] Design & Diagnostics

Oil to Gas Firing Conversion

Pulverized Coal Firing Systems

Steam Cycle Optimization

Superheater Design

Waste Heat Recovery Systems

![Cogeneration / Combined Heat & Power [CHP]](https://www.designboiler.com/wp-content/uploads/2019/04/C-12.jpg)

![Heat Recovery Steam Generator [HRSG] Design & Diagnostics](https://www.designboiler.com/wp-content/uploads/2019/04/C-13.jpg)