CAPABILITIES

Boiler Performance Analysis & Computer Modelling

Boiler heat transfer is significantly different to that of a typical industrial process and needs to be analyzed and modelled using purpose-built software. This software must incorporate features to address the following issues and nuances of steam raising plant:

- Radiation tends to play a dominant role in the overall heat transfer and requires a significantly more complex assessment than other heat transfer modes.

- Heating surfaces can have unusual configurations and orientations with respect to gas flows making heat transfer performance difficult to assess.

- Extended fin (including square gill) tubing used to recover low grade heat at the back end of many boilers requires algorithms which are not normally available in industrial heat exchanger and process analysis software.

- Superheater temperature control needs very specific attention in any modelling exercise. Spray attemperation can have a profound effect on superheater metal temperatures and the steam and spraywater configuration paths can be complicated by the use of so called “sweet water condensers”. Alternatively, non-contact attemperation systems also need special consideration as they are normally incorporated into the boiler’s internal circulation system .

- Accurate assessment of water cooled enclosures and cavity heat absorption can have a significant impact on the accuracy of boiler performance predictions and internal circulation modelling results.

- Boilers often utilize airheating systems which can be difficult to analyse accurately.

Our extensive range of boiler performance modelling software includes software packages that model the entire gas side process within almost any boiler, including;

- Furnace performance; both burner fired (gas, oil and pulverized coal) and grate fired (biomass and coal) boilers.

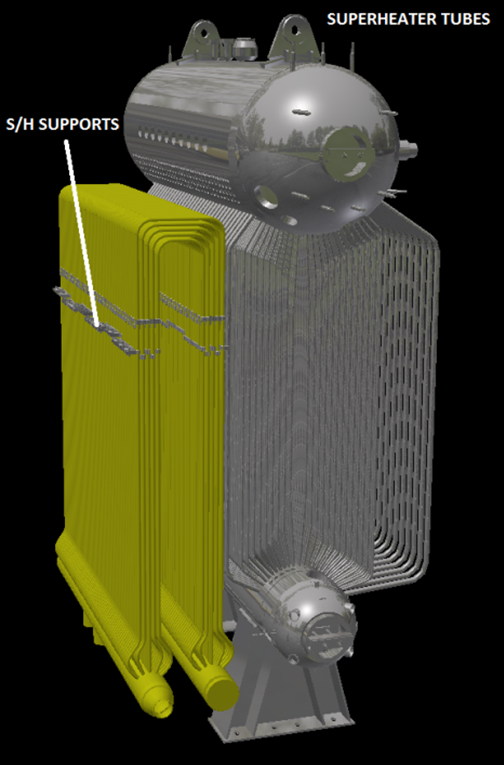

- Convection pass heat transfer and performance with a fired and waste heat boiler and can include superheaters, reheaters, steam cooled walls and evaporative heating surfaces.

- Economiser performance including those constructed from both spiral wound and various square gill finned tubes.

- Software that can predict airheater performance.

- Software to evaluate the performance of heat recovery steam generators [HRSG] and waste heat boiler systems.

These programs have been field tested on numerous boilers in many different industries over several decades.

A demonstration of our boiler performance modelling capabilities can be found here and our finned tube performance modelling capabilities here.

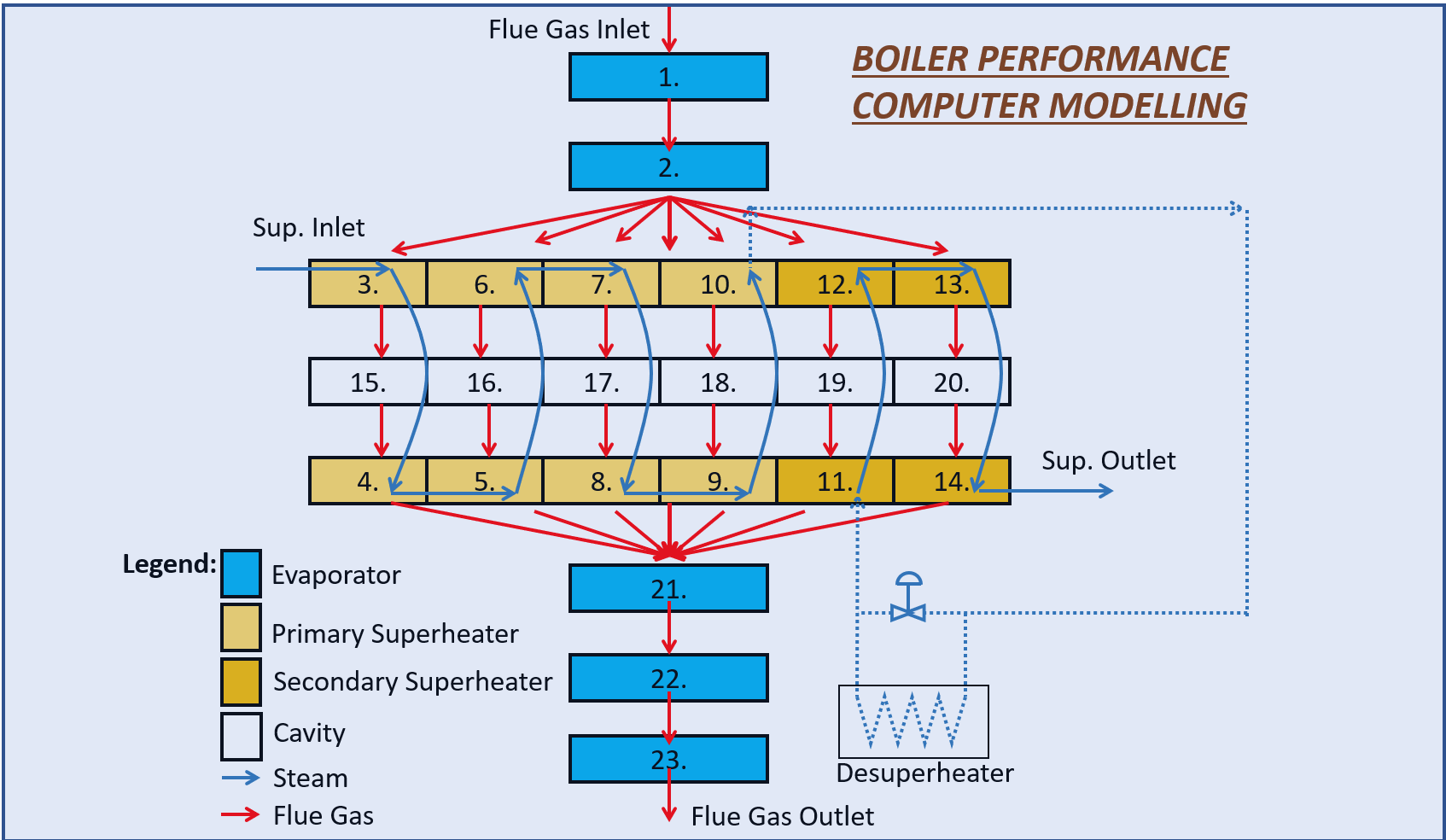

BOILER PERFORMANCE COMPUTER MODELING

Typical boiler modelling architecture for assessing boiler performance. |

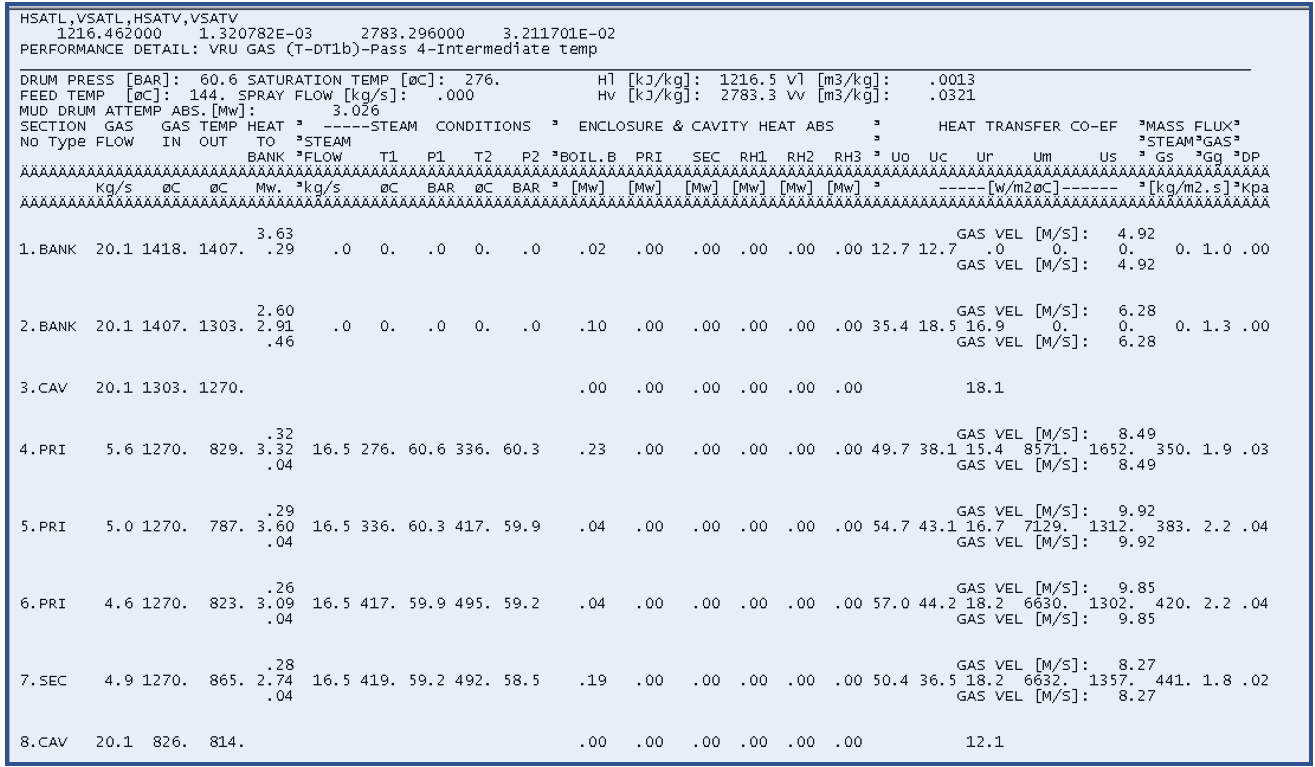

BOILER PERFORMANCE PROGRAM OUTPUT

Sample computer model output used for evaluation of boiler performance. |