Whether you’re a boiler owner, consultant or third party fabricator, we can address most of your boiler design requirements, including reviewing and modelling new boiler plant before it is purchased, or achieving efficiency improvements in existing boiler plant.

BOILER DESIGN SERVICE

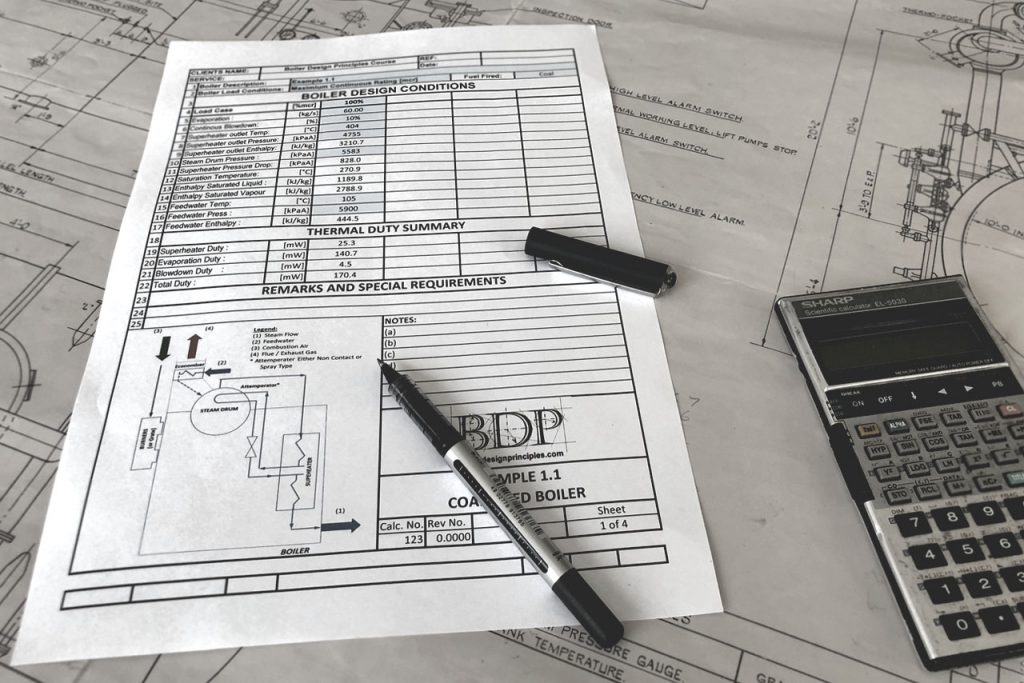

Comprehensive third party design review & risk assessment of low cost boilers sourced from less prominent boiler manufacturers. The service includes thermodynamic boiler performance modelling, circulation analysis, grate and burner fired combustion system review and any other relevant findings. Design Boiler is skilled and experienced in undertaking the necessary computer modelling , design work and field testing required for converting bagasse fired boilers to

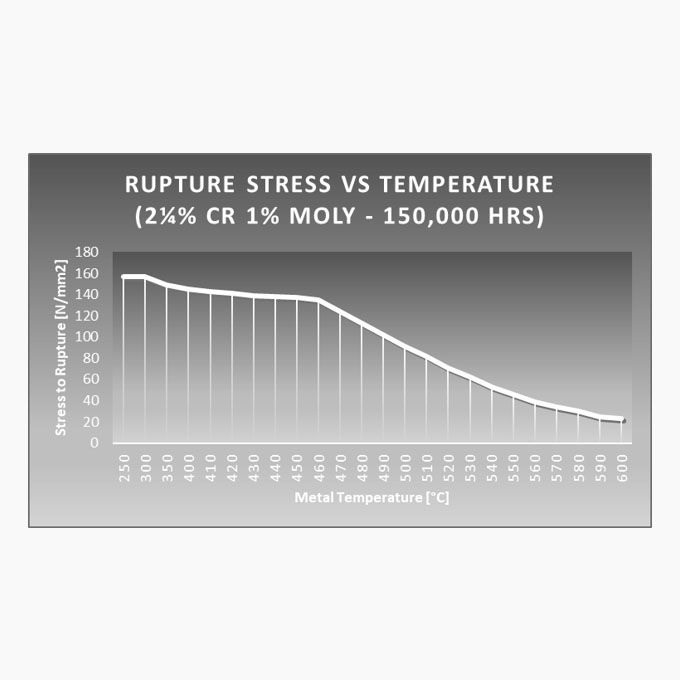

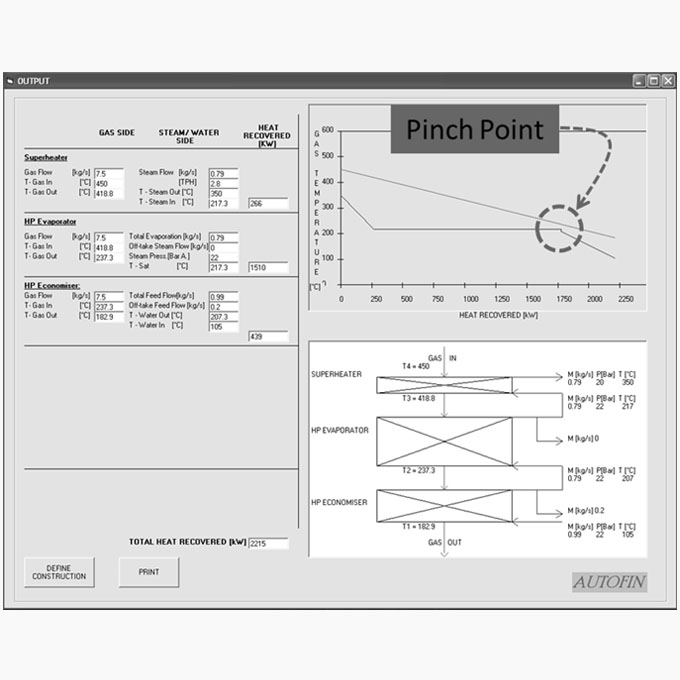

coal firing. Boiler heat transfer is significantly different to that of a typical industrial process and needs to be analyzed and modelled using purpose-built software. Our extensive range of boiler performance modelling software includes software packages that model the entire gas side process within almost any boiler. A well-designed boiler circulation system is usually very robust and able to withstand a wide range of operational upset conditions. Conversely a poorly designed system may exhibit a multitude of operational problems such as: frequent tube failures, drum level control instability, superheater tube failures and turbine fouling. Design Boiler are boiler circulation experts and can model the circulation, and resolve circulation defects in almost any sub-critical boiler. The utilization of waste heat in industry for the production of steam to generate electricity has grown steadily since the 1970’s and Design Boiler have been designing waste heat recovery systems for much of this time. Rising fuel and electricity costs along with increasing concerns about environmental emissions have seen a gradual rise in the number of cogeneration and combined heat & power [CHP] plants globally. Design Boiler has been involved in the design and the diagnostics of problems with HRSG’s for many years. Our technology has also been utilized to verify the suitability of deck mounted HRSGs in key offshore marine installations and to design HRSG’s for industrial co-generation plants. Design Boiler have the computer resources and experienced to undertaking the necessary thermodynamic modelling ,design work and field testing required by certification authorities for converting oil fired boilers to gas firing. Typically an oil fired Marine boiler destined for operation on an off shore Floating Production Storage & Offloading [FPSO] platform will need conversion from oil to gas firing. Design Boiler is able to undertake the necessary redesign of the boiler and prepare the required documentation for submission to the relevant marine class authority ( ABS, Lloyds, DNV etc.). A poorly designed or problematic steam cycle can impact on overall plant efficiency and significantly increase energy costs. High flash steam losses and excessive condensate makeup are all symptoms of a badly balanced steam cycle which can have detrimental effects on the performance of downstream appliances such as deaerators and steam turbines. Design Boiler have the necessary expertise and experience to optimise the most vexing steam cycle challenges. The most critical aspect of a superheater design is accurate metal temperature prediction, to enable the selection of suitable tube materials, that will achieve an acceptable design life. Design Boiler provide this expertise with our complete superheater design and modelling service. Superheaters operate within a very arduous environment and are often designed at the extreme end of their tube’s metallurgical limits. They are the first receivers of the hottest flue gases generated within the furnace, and are constantly subject to direct radiation from the combustion process. Most boiler design standards (ASME, BS, ISO, Lloyds, ABS etc) require the superheater to be designed to achieve a minimum design life in terms of operating hours and Design Boiler can provide a design to meet this criteria. It was the Arab Oil Embargo of the 1970’s that forced industry to become more energy efficient and invest in low grade heat recovery systems. Following this global event it was soon realized that the cost saving engineering strategies utilized in the design of waste heat recovery systems also produced significant benefits for the environment. Design Boiler has been involved in the design and troubleshooting problems in a waste heat recovery systems over much of this period.Boiler Design Review Service

Bagasse to Coal Firing Conversions

Boiler Performance Analysis & Computer Modelling

Boiler Circulation Analysis

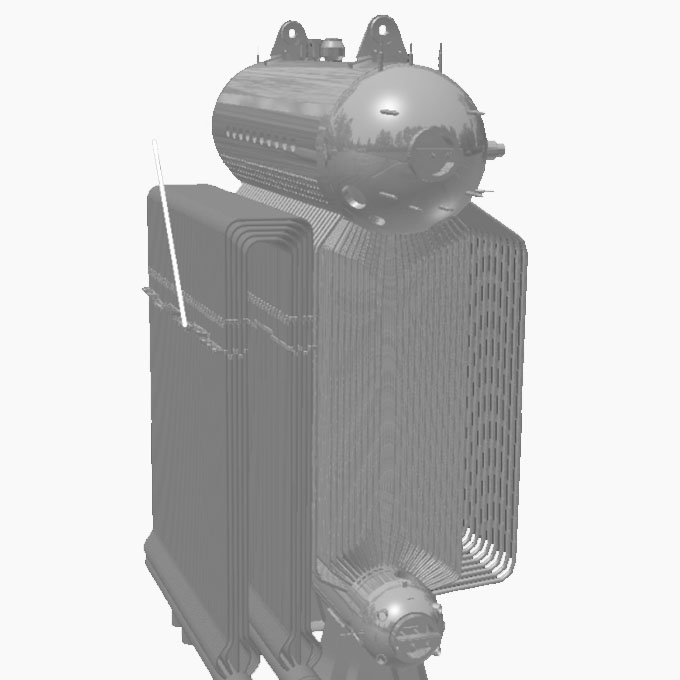

Cogeneration / Combined Heat & Power [CHP]

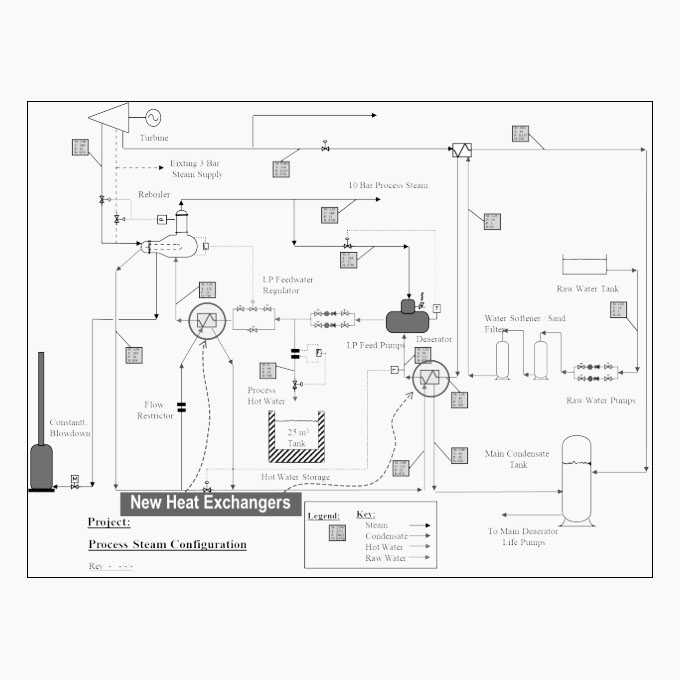

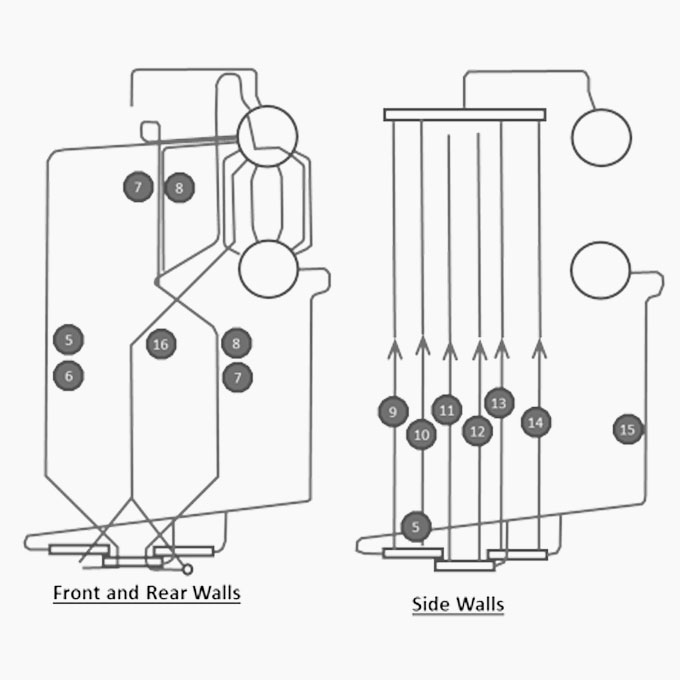

Heat Recovery Steam Generator [HRSG] Design & Diagnostics

Oil to Gas Firing Conversion

Steam Cycle Optimization

Superheater Design

Waste Heat Recovery Systems

![Cogeneration / Combined Heat & Power [CHP]](https://www.designboiler.com/wp-content/uploads/2019/04/C-12.jpg)

![Heat Recovery Steam Generator [HRSG] Design & Diagnostics](https://www.designboiler.com/wp-content/uploads/2019/04/C-13.jpg)